Streamline your production with our weigh price labellers

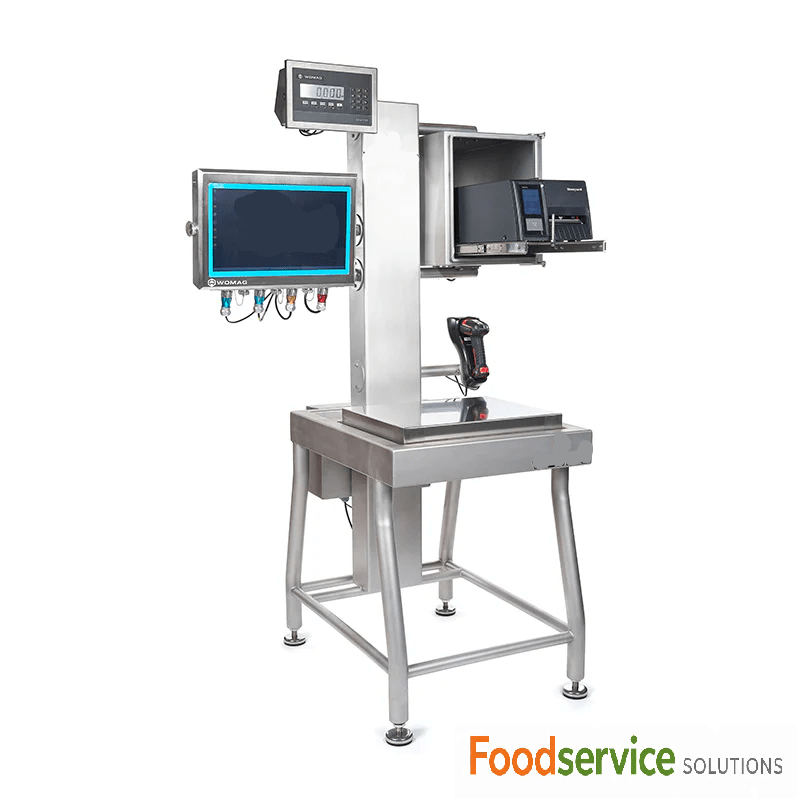

WOMAG OCM-PRO Weigh Price Labeller

Dibal LS-5000 Automatic Weigh Price Labeller

Dibal LP-5000 Touch Screen Manual Labeller

Ensuring Food Safety and Seamless Integration

Factory traceability is at the core of the OCM-PRO’s capabilities, meticulously tracking products from raw materials to finished goods. This comprehensive system ensures food safety and facilitates compliance with regulations such as HACCP, BRCGS, and FSMA. Beyond traceability, the integrated software supports inventory and stock management, order processing, recipe and batch management, automated labelling, dispatch, and audit readiness. The OCM-PRO seamlessly integrates with existing logistics and distribution systems and supports advanced label design software like BarTender® and Dev Express. Trusted by catering butchers, local authorities, seafood processors, pasta manufacturers, and many more, the OCM-PRO is a proven solution for diverse food processing needs.

Versatility, Hygiene, and Unwavering Support

This multi-application machine goes beyond simple price labelling, handling average weight, catch weight, ERP/traceability, and recipe management. Designed with hygiene as a top priority, the OCM-PRO features a full stainless steel construction (AISI 304 standard, with optional 316), an open structure for effortless cleaning and rapid drying, and IP54 to IP69K protection ratings. Its versatile configuration allows for a wide array of screen sizes, printers, scales, scanners, indicators, and software modules to be integrated, tailoring the system to your specific requirements. Backed by industry-leading support, the W-OCM comes with a 2-year warranty, rapid service exchange, and 24/7 remote assistance. The professional panel build includes customer-disconnectable weighing equipment and integrated Dini Tools for convenient remote support and diagnostics.

OCM Pro Specifications

Dibal LS-5000 Specifications

Call us today on 0121 724 0885 for more information.

Or Email us at enquires@foodservices.solutions